Products

-

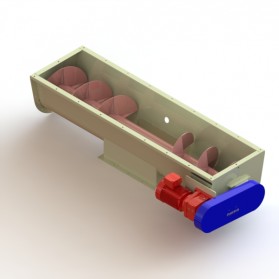

Auger

Each design is unique in its own form to suit varied situations. Dalein provides a variety of specifically designed augers, for horizontal or inclined transport of bulk goods and materials. Augers are constructed from durable materials and provide an efficient, economical and dependable conveying medium, reflecting the benefits of our sound engineering experience.

Advantages of Dalein Agriplan's well-designed flight conveyers are clean, low energy consumption and dust free operation Augers, with favourable dimensions and a great degree of maintenance-friendliness as an extra touch.

The transport capacity and the variety of products that can be moved with our augers are exceptionally high. Augers can also be used as discharge and capacity control equipment.

The shaft with the scroll moves the product from the intake trough to the outlet on the drive side. The product does not rotate and just moves forward. The drive group consists of an electrical gearbox motor with optimal frequency controller for full control. Equipment and accessories are manufactured both for straight forward conveyors and for complete systems in large turn-key projects.

-

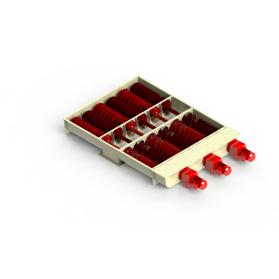

Live Bottom

Live bottoms transport bulk materials, from the hopper, silo or holding bin, utilising a screw to transport the material. Normally the feeder screw will have a variable pitch under the inlet to balance the flights at full pitch, reflecting the benefits of sound engineering experience. Dalein Agriplan's Live Bottoms are constructed from durable materials and provide an efficient, economical and dependable conveying method. We engineer and manufacture live bottom screw feeders according to your needs.

-

Bagging units - Nett Weigher

Our nett bag weighers are designed to receive product in a continuous process, in mash or pelleted form. It weighs an amount as quickly and accurately as possible. The weigher weighs the product in a small hopper and discharges directly into a bag. The bag is then transferred to the next point to be stitched. The nett bag weigher has a capacity of ±12t/h.

Dalein’s semi-automatic bagging unit is unique and very simple in construction, with few movable parts. It is easy to maintain and most of all, easy for the user to operate. The computer secures an exact weighing and registers each weighing, enabling the user to print on paper or read from the display, the number of bags having been weighed. The computer is pre-set to the required amount to be weighed. The semi-automatic bagging unit is delivered complete with electrical control board.

-

Conveyor Belt

The Sewing Conveyor belt is usually used beneath the Nett Weigher. The feed is dispatched into a bag which is then released onto the conveyor belt. The conveyer belt transports the open bag of feed at the correct speed through the sewing machine. The sewing machine stitches the bag of feed shut, which is now ready to be transported. Dalein Agriplan provides 2 types of conveyors - horizontal or inclined - to suit the client’s needs.

-

Intake Grid

Dalein Agriplan has various standard sizes of intake grids to suit the client’s building and requirements. The grids are designed so that a truck, filled with feed, can drive over it. The grids are level with the floor and are usually on top of a concrete pit or a live bottom.

-

Bulk Intake System

Bulk intakes can revcieve raw materials in large amounts. Dalein Agriplan provides highly efficeint raw material intake systems for storage of raw material for futher processing. It consist of a concrete pit or live bottoms along with transport elements to the storage destination.

-

Weigh Bridge

Dalein Agriplan’s weigh bridge is used to weigh an entire truck or vehicle and their contents. Due to the large scale, it’s usually mounted permanently on a concrete foundation. The load carried is calculated by measuring the weight of the empty vehicle and then with its contents. The weigh bridge is usually located under the overhead bridge to simplify the process.

-

Overhead Bridge

The overhead bridge is usually located across the weigh bridge, to simplify the process of before and after weighing. The overhead bridge conveys the final product that is ready to be transported. Dalein Agriplan has designed the overhead bridge to transport the final product from inside the plant to outside, with a covered gantry for easy maintenance and to protect the equipment from the weather conditions South Africans may encounter. The dispatch is designed to minimise product waste.

The overhead bridge is a set of bins for the final product, located on the outside of the feed mill. It’s designed so that a feed-tanker can drive underneath the bridge, where the feed is released from the bins into the feed-tanker. A large weigh-scale is also fitted on the ground under the bridge, to weigh the feed-truck.

-

BOA - Compactor

A double-walled mixing chamber in which steam and liquids are added and the mixture is compacted using a hydraulically operated compacting chamber. Generously sized paddles, adjustable in both height and pitch, guarantee a homogenous mixture and a hygienic process. The mixture is introduced into the compacting chamber where a rotating three-roller head, presses it through two conical friction rings.

-

Conditioner

The stainless-steel conditioner mixer has large paddles whose height and angle can be

adjusted to provide homogenous mixing and a hygienic process.The robust, low-maintenance machine can be combined with a feeder screw and steam set

and contributes to an optimum absorption of steam and liquids.There is a choice of two options: a standard conditioner mixer and an insulated, electrically

heated version which minimises the formation of condensation and premature cooling.

Development and engineering details make the difference in this stainless-steel conditioner.

Large-scale paddles whose height and angle can be adjusted generate homogenous mixing

and a hygienic process.The conditioner is often supplied in combination with a feeder screw and steam set.

Homogenous mixing and hygienic process. The benefits are:

- Optimum absorption of steam and liquids.

- Robust housing construction.

- Easy to clean.

- Longer maintenance intervals.

- Simple design.