Products

-

Ribbon Mixers

Dalein Agriplan’s Ribbon Mixer has 3 different mixing capacitie:

- 1 ton

- 1.5 ton

- 2 ton

The main benefits of these Ribbon Mixers are that they are cost effective and give a homogeneous mix within 3 to 4 minutes. These mixers are typically used where dry animal feeds are mixed. The Ribbon Mixers have 2 discharging methods:

- Standard double bomb drop doors along the length of the mixer for quick discharging

- A slide gate

-

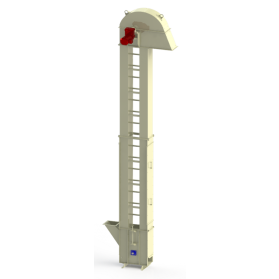

Bucket Elevator

Bucket elevators are very efficient equipment for the continuous, vertical, dust-free transport of granulated and powdered bulk materials. Dalein Agriplan's bucket elevators are designed to stand on its own with or without support or in a structure. Material is fed into the boot of the elevator via an integrated inlet chute. The elevator belt runs over a pulley both at the top and at the bottom of the elevator. Buckets are attached and fitted at equal spaces to the belt by specialised elevator bolts which have a flat head, thereby minimizing interference with the head and tail end pulleys.

The goal is always to minimise spillage and thereby increase efficiency, while avoiding and designing around potential high-wear areas.

The top pulley is driven while the bottom pulley is fitted with a tensioning device. The base can be fitted with one or two intake chutes.

When an elevator is discharging, both gravity and centrifugal forces play an important role. The design of the inlet and discharge connections has a major effect on the capacity of the elevator. The content and shape of the elevator buckets, the bucket spacing, the belt speed and the pulley diameters also play an important role.

Some of the key design objectives are:

• Optimal performance

• Life span

• Maintainability

-

Magnet Box

Dalein Agriplan uses magnet boxes, fitted with powerful permanent magnetic plates, to remove metal particles from raw material and animal feed in transport. This decreases the possibility of metal parts ending up in the final product or damaging machinery. These boxes can be used in other food and plastic industries as well. The sizes of the magnet boxes can be custom designed to fit your plant’s needs.

-

Silo's

Storage of grain and seed products requires the utmost care and control at the same time. Many of the world's crops are lost in storage, due to the uncontrollable development of heat and moisture. Therefore, monitoring and controlling of temperatures are of vital importance in modern grain handling. No silo project is too big or too small for Dalein Agriplan – whether the solution applies to a large or small, square or round silo solution. At Dalein Agriplan we provide 2 types of silos for your convenience:

• Round silos Round silos are suitable for large storage capacities. Dalein Agriplan provides the option of round silos manufactured by our trustworthy suppliers. The capacity of the largest round silo goes up to 4000 tons.

• Square silos Square silos are ideal for the use of inside batching and holding purposes. Square silos can be used in dual row placement, with capacities of 6 - 15 tons. For bulk materials, square is the right shape for maximum capacity. Square silos should be cladded if used outside for the overload bridge out-loading system.

-

Liquid Dosing Unit

Dalein Agriplan provides liquid additions of water, animal oil and molasses that is added by a volume based flow meter into a mixer, fat coater, lick plant or a conditioner.

-

Pellet Press

Dalein Agriplan's expertise in the pelleting process focuses on creating a pellet that is durable and tough enough to resist breakage during handling. Our pelleting press enables companies to pellet a wide variety of different raw materials. Pellet machines can be fitted with a twin or single conditioner with a recursion time barrel.

The pelleting process begins with a conditioning process where steam is homogeneously mixed with the ingredients at a temperature of up to 75°C. A knife system systematically cuts the pelletized product from the die and the still warm pellets proceed onwards for cooling.

Optimum meal preparation is essential for maximum press capacity. Meal, molasses and steam are mixed in the (conditioning) mixer to form a mixture that can easily be pressed. The entire supply of meal, steam and liquids is controlled by a fully automated PLC system.

-

Overhead Bridge

The overhead bridge is usually located across the weigh bridge, to simplify the process of before and after weighing. The overhead bridge conveys the final product that is ready to be transported. Dalein Agriplan has designed the overhead bridge to transport the final product from inside the plant to outside, with a covered gantry for easy maintenance and to protect the equipment from the weather conditions South Africans may encounter. The dispatch is designed to minimise product waste.

The overhead bridge is a set of bins for the final product, located on the outside of the feed mill. It’s designed so that a feed-tanker can drive underneath the bridge, where the feed is released from the bins into the feed-tanker. A large weigh-scale is also fitted on the ground under the bridge, to weigh the feed-truck.

-

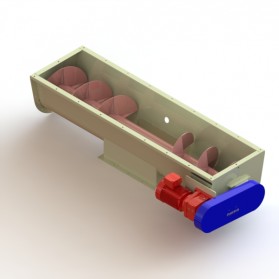

Auger

Each design is unique in its own form to suit varied situations. Dalein provides a variety of specifically designed augers, for horizontal or inclined transport of bulk goods and materials. Augers are constructed from durable materials and provide an efficient, economical and dependable conveying medium, reflecting the benefits of our sound engineering experience.

Advantages of Dalein Agriplan's well-designed flight conveyers are clean, low energy consumption and dust free operation Augers, with favourable dimensions and a great degree of maintenance-friendliness as an extra touch.

The transport capacity and the variety of products that can be moved with our augers are exceptionally high. Augers can also be used as discharge and capacity control equipment.

The shaft with the scroll moves the product from the intake trough to the outlet on the drive side. The product does not rotate and just moves forward. The drive group consists of an electrical gearbox motor with optimal frequency controller for full control. Equipment and accessories are manufactured both for straight forward conveyors and for complete systems in large turn-key projects.

-

Steam

Adding steam to the production process for animal feeds improves the compressibility (an increase in the press capacity of 20% is no exception) and the condition of the laying mash, among other things. Steam inactivates micro-organisms while the sensory properties (including aroma, taste and texture) of the product mix are retained.

For the production of high-quality (dry) steam – the quality is determined by pressure and temperature – PTN supplies steam lines and steam injection systems on mixers, presses, expanders and compactors.

Characteristic of the injection systems is the volume-increasing drainage vessel after the reducing unit in which a steam flash, and thus superheated dry steam, is generated.

The compact systems are available with a capacity of 150 - 2.500 kg/hr, are easy to install and use relatively little energy.

-

Belt Conveyor

Dalein Agriplan designed a belt conveyor with a wide variety that can meet the client’s feed milling specifications. Belt conveyors can be at an incline of up to a max of 40° and can move up to a speed of ±1.2m/sec. Lengths can be custom designed to suit each feed plant needs with widths varying between 0.9m – 1.5m. Belt conveyors are manufactured with a safety feature to ensure all personal safety as well with an automatic tracking for accurate belt movement and can be used indoors or outdoors.

-

Final Product Bin

Dalein Agriplan provides final product bins that can hold 11-23m³. Final product bins are used to store the final product before it is bagged by the Nett weiger/Gross weigher or moved to be pelletized or transported by a chain conveyor to the overhead bulk dispatch bins.

-

Bagging units - Nett Weigher

Our nett bag weighers are designed to receive product in a continuous process, in mash or pelleted form. It weighs an amount as quickly and accurately as possible. The weigher weighs the product in a small hopper and discharges directly into a bag. The bag is then transferred to the next point to be stitched. The nett bag weigher has a capacity of ±12t/h.

Dalein’s semi-automatic bagging unit is unique and very simple in construction, with few movable parts. It is easy to maintain and most of all, easy for the user to operate. The computer secures an exact weighing and registers each weighing, enabling the user to print on paper or read from the display, the number of bags having been weighed. The computer is pre-set to the required amount to be weighed. The semi-automatic bagging unit is delivered complete with electrical control board.

-

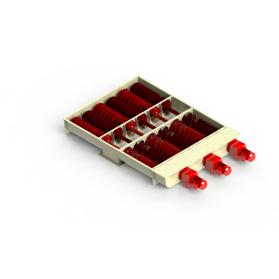

Live Bottom

Live bottoms transport bulk materials, from the hopper, silo or holding bin, utilising a screw to transport the material. Normally the feeder screw will have a variable pitch under the inlet to balance the flights at full pitch, reflecting the benefits of sound engineering experience. Dalein Agriplan's Live Bottoms are constructed from durable materials and provide an efficient, economical and dependable conveying method. We engineer and manufacture live bottom screw feeders according to your needs.

-

Rotary Sifter

Rotary sifters are used to remove grit and fine objects from the feed flow. That is why Dalein Agriplan offers a wide range of different options to help you maximise productivity and more importantly, your profitability. Dalein Agriplan offers a wide range of different sifters to meet your unique requirements.

-

Inteqnion Control System (Siemens based PLC & SCADA system)

Inteqnion – Process automation Inteqnion is specialized in the design, build and installation of control systems for the batch and continuous controlled process industry. Our strength is asset management and its improvement. We help our clients to cut costs, reduce risk, improve results and to optimize the preformance of their assets. We want more than just meet your needs: we take on the challenge to exceed your expectations.