Products

-

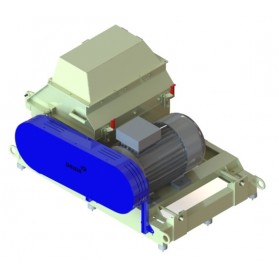

Conditioner

The stainless-steel conditioner mixer has large paddles whose height and angle can be

adjusted to provide homogenous mixing and a hygienic process.The robust, low-maintenance machine can be combined with a feeder screw and steam set

and contributes to an optimum absorption of steam and liquids.There is a choice of two options: a standard conditioner mixer and an insulated, electrically

heated version which minimises the formation of condensation and premature cooling.

Development and engineering details make the difference in this stainless-steel conditioner.

Large-scale paddles whose height and angle can be adjusted generate homogenous mixing

and a hygienic process.The conditioner is often supplied in combination with a feeder screw and steam set.

Homogenous mixing and hygienic process. The benefits are:

- Optimum absorption of steam and liquids.

- Robust housing construction.

- Easy to clean.

- Longer maintenance intervals.

- Simple design.

-

Conveyor Belt

The Sewing Conveyor belt is usually used beneath the Nett Weigher. The feed is dispatched into a bag which is then released onto the conveyor belt. The conveyer belt transports the open bag of feed at the correct speed through the sewing machine. The sewing machine stitches the bag of feed shut, which is now ready to be transported. Dalein Agriplan provides 2 types of conveyors - horizontal or inclined - to suit the client’s needs.

-

Crumbler

We provide 2 types of crumblers&rsquo

• The local Dalein Agriplan crumblers&rsquo

• PTN crumblers&rsquo

The crumbles’ are specifically designed for crumb production of various feeds. Two spring bolted rollers are specially spaced to gently crumble the pellets into specified smaller pieces. For reliability during use, all the crumbles’ are fitted with specific fluted and machined rollers.

-

ESW Control System (Locally Develop Control Units)

Electronic System Wrights (Pty) Ltd. By Edwin van de Wiel (Managing Director) Specialising in Industrial Electronic Design and Manufacturing for Automation since 1988. Working with the Dalein Group companies from 1992 for Batch Weighing systems and currently have more than sixty sites running with our systems. The application of Y-Series controllers, our newest control system, are for cost effective Batch Weighing systems including Bulk Materials transport, Pellet Presses, Gross and Net Bagging as used in feed factories. As service to our clients we also design the electrical integration with the industrial plants and help to commission the systems. The Y-Series controller modules are very flexible and are used on standalone systems of between nine and 600 input/output points. These systems become very cost effective as 95% of the software is shared between projects, from the smallest to largest, offering bug free and reliable installation and operation. All the modules run on our real-time communications operating system (RTCOS) with the applications and OS written in "C" for reliability and easy maintenance. Other applications include energy efficient and accurate Industrial Chilling and Freezing, integrated with Energy and Building Management, and SCADA systems. Currently developing a high security Y-Series Gateway that will fully integrate with the internet for IoT and Cloud applications.

-

Fat Coating

We offer a fat coating system that can enhance the energy and palatability of feed. Dalein Agriplan provides a batching fat coating system that consists of an inlet hopper that flows into a paddle mixer on load cells that can mix up to 20t/h. The fat coated product is then dispatched into a holding bin.

Fat is sprayed onto the pellets by a specially designed manifold. By accurately weighing the bulk to the specified weight the precise percentage of oil can then be used to coat the pellets with each batch.

-

Final Product Bin

Dalein Agriplan provides final product bins that can hold 11-23m³. Final product bins are used to store the final product before it is bagged by the Nett weiger/Gross weigher or moved to be pelletized or transported by a chain conveyor to the overhead bulk dispatch bins.

-

Hammer Mills

Various Dalein Agriplan Hammer Mills are available. Capacities range from 3 to 20 tons per hour. Our unique asymmetrical design allows for optimum power-to-capacity ratios without aspiration. Aspiration remains available to enhance the capacity per kilowatt and ensure more homogeneous particle sizes.

-

Intake Grid

Dalein Agriplan has various standard sizes of intake grids to suit the client’s building and requirements. The grids are designed so that a truck, filled with feed, can drive over it. The grids are level with the floor and are usually on top of a concrete pit or a live bottom.

-

Inteqnion Control System (Siemens based PLC & SCADA system)

Inteqnion – Process automation Inteqnion is specialized in the design, build and installation of control systems for the batch and continuous controlled process industry. Our strength is asset management and its improvement. We help our clients to cut costs, reduce risk, improve results and to optimize the preformance of their assets. We want more than just meet your needs: we take on the challenge to exceed your expectations.

-

Liquid Dosing Unit

Dalein Agriplan provides liquid additions of water, animal oil and molasses that is added by a volume based flow meter into a mixer, fat coater, lick plant or a conditioner.