Products

-

Conditioner

The stainless-steel conditioner mixer has large paddles whose height and angle can be

adjusted to provide homogenous mixing and a hygienic process.The robust, low-maintenance machine can be combined with a feeder screw and steam set

and contributes to an optimum absorption of steam and liquids.There is a choice of two options: a standard conditioner mixer and an insulated, electrically

heated version which minimises the formation of condensation and premature cooling.

Development and engineering details make the difference in this stainless-steel conditioner.

Large-scale paddles whose height and angle can be adjusted generate homogenous mixing

and a hygienic process.The conditioner is often supplied in combination with a feeder screw and steam set.

Homogenous mixing and hygienic process. The benefits are:

- Optimum absorption of steam and liquids.

- Robust housing construction.

- Easy to clean.

- Longer maintenance intervals.

- Simple design.

-

ESW Control System (Locally Develop Control Units)

Electronic System Wrights (Pty) Ltd. By Edwin van de Wiel (Managing Director) Specialising in Industrial Electronic Design and Manufacturing for Automation since 1988. Working with the Dalein Group companies from 1992 for Batch Weighing systems and currently have more than sixty sites running with our systems. The application of Y-Series controllers, our newest control system, are for cost effective Batch Weighing systems including Bulk Materials transport, Pellet Presses, Gross and Net Bagging as used in feed factories. As service to our clients we also design the electrical integration with the industrial plants and help to commission the systems. The Y-Series controller modules are very flexible and are used on standalone systems of between nine and 600 input/output points. These systems become very cost effective as 95% of the software is shared between projects, from the smallest to largest, offering bug free and reliable installation and operation. All the modules run on our real-time communications operating system (RTCOS) with the applications and OS written in "C" for reliability and easy maintenance. Other applications include energy efficient and accurate Industrial Chilling and Freezing, integrated with Energy and Building Management, and SCADA systems. Currently developing a high security Y-Series Gateway that will fully integrate with the internet for IoT and Cloud applications.

-

Weigh Bridge

Dalein Agriplan’s weigh bridge is used to weigh an entire truck or vehicle and their contents. Due to the large scale, it’s usually mounted permanently on a concrete foundation. The load carried is calculated by measuring the weight of the empty vehicle and then with its contents. The weigh bridge is usually located under the overhead bridge to simplify the process.

-

Batching Scale

Our batching scale provides a wide variety of scales batching between 500kg – 2tons. Our unique designed allows for free flowing of difficult products like Lucerne, citrus pulp, silage etc.

-

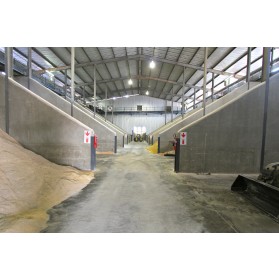

Bunkers

Storage of raw materials requires the utmost care and control at the same time. Many of the world's crops are lost during storage due to the lack of heat and moisture control. No bunker project is too complicated or too simple for Dalein Agriplan – whether the solution applies to large or small bunkers. Open bunkers are ideal for the use of inside batching and holding purposes. For bulk materials, square is the right shape for maximum capacity.

-

Ribbon Mixers

Dalein Agriplan’s Ribbon Mixer has 3 different mixing capacitie:

- 1 ton

- 1.5 ton

- 2 ton

The main benefits of these Ribbon Mixers are that they are cost effective and give a homogeneous mix within 3 to 4 minutes. These mixers are typically used where dry animal feeds are mixed. The Ribbon Mixers have 2 discharging methods:

- Standard double bomb drop doors along the length of the mixer for quick discharging

- A slide gate

-

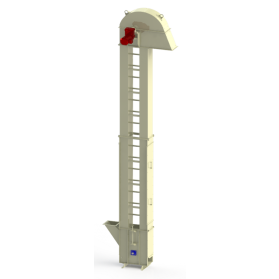

Bucket Elevator

Bucket elevators are very efficient equipment for the continuous, vertical, dust-free transport of granulated and powdered bulk materials. Dalein Agriplan's bucket elevators are designed to stand on its own with or without support or in a structure. Material is fed into the boot of the elevator via an integrated inlet chute. The elevator belt runs over a pulley both at the top and at the bottom of the elevator. Buckets are attached and fitted at equal spaces to the belt by specialised elevator bolts which have a flat head, thereby minimizing interference with the head and tail end pulleys.

The goal is always to minimise spillage and thereby increase efficiency, while avoiding and designing around potential high-wear areas.

The top pulley is driven while the bottom pulley is fitted with a tensioning device. The base can be fitted with one or two intake chutes.

When an elevator is discharging, both gravity and centrifugal forces play an important role. The design of the inlet and discharge connections has a major effect on the capacity of the elevator. The content and shape of the elevator buckets, the bucket spacing, the belt speed and the pulley diameters also play an important role.

Some of the key design objectives are:

• Optimal performance

• Life span

• Maintainability

-

Magnet Box

Dalein Agriplan uses magnet boxes, fitted with powerful permanent magnetic plates, to remove metal particles from raw material and animal feed in transport. This decreases the possibility of metal parts ending up in the final product or damaging machinery. These boxes can be used in other food and plastic industries as well. The sizes of the magnet boxes can be custom designed to fit your plant’s needs.

-

Silo's

Storage of grain and seed products requires the utmost care and control at the same time. Many of the world's crops are lost in storage, due to the uncontrollable development of heat and moisture. Therefore, monitoring and controlling of temperatures are of vital importance in modern grain handling. No silo project is too big or too small for Dalein Agriplan – whether the solution applies to a large or small, square or round silo solution. At Dalein Agriplan we provide 2 types of silos for your convenience:

• Round silos Round silos are suitable for large storage capacities. Dalein Agriplan provides the option of round silos manufactured by our trustworthy suppliers. The capacity of the largest round silo goes up to 4000 tons.

• Square silos Square silos are ideal for the use of inside batching and holding purposes. Square silos can be used in dual row placement, with capacities of 6 - 15 tons. For bulk materials, square is the right shape for maximum capacity. Square silos should be cladded if used outside for the overload bridge out-loading system.

-

Liquid Dosing Unit

Dalein Agriplan provides liquid additions of water, animal oil and molasses that is added by a volume based flow meter into a mixer, fat coater, lick plant or a conditioner.