Products

-

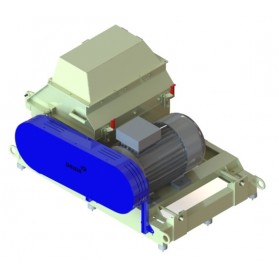

Hammer Mills

Various Dalein Agriplan Hammer Mills are available. Capacities range from 3 to 20 tons per hour. Our unique asymmetrical design allows for optimum power-to-capacity ratios without aspiration. Aspiration remains available to enhance the capacity per kilowatt and ensure more homogeneous particle sizes.

-

Twin Shaft Paddle Mixers

Various Dalein Agriplan Hammer Mills are available. Capacities range from 3 to 20 tons per hour. Our unique asymmetrical design allows for optimum power-to-capacity ratios without aspiration. Aspiration remains available to enhance the capacity per kilowatt and ensure more homogeneous particle sizes.

-

Ribbon Mixers

Dalein Agriplan’s Ribbon Mixer has 3 different mixing capacitie:

- 1 ton

- 1.5 ton

- 2 ton

The main benefits of these Ribbon Mixers are that they are cost effective and give a homogeneous mix within 3 to 4 minutes. These mixers are typically used where dry animal feeds are mixed. The Ribbon Mixers have 2 discharging methods:

- Standard double bomb drop doors along the length of the mixer for quick discharging

- A slide gate

-

Crumbler

We provide 2 types of crumblers&rsquo

• The local Dalein Agriplan crumblers&rsquo

• PTN crumblers&rsquo

The crumbles’ are specifically designed for crumb production of various feeds. Two spring bolted rollers are specially spaced to gently crumble the pellets into specified smaller pieces. For reliability during use, all the crumbles’ are fitted with specific fluted and machined rollers.

-

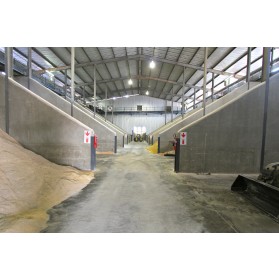

Bunkers

Storage of raw materials requires the utmost care and control at the same time. Many of the world's crops are lost during storage due to the lack of heat and moisture control. No bunker project is too complicated or too simple for Dalein Agriplan – whether the solution applies to large or small bunkers. Open bunkers are ideal for the use of inside batching and holding purposes. For bulk materials, square is the right shape for maximum capacity.

-

Silo's

Storage of grain and seed products requires the utmost care and control at the same time. Many of the world's crops are lost in storage, due to the uncontrollable development of heat and moisture. Therefore, monitoring and controlling of temperatures are of vital importance in modern grain handling. No silo project is too big or too small for Dalein Agriplan – whether the solution applies to a large or small, square or round silo solution. At Dalein Agriplan we provide 2 types of silos for your convenience:

• Round silos Round silos are suitable for large storage capacities. Dalein Agriplan provides the option of round silos manufactured by our trustworthy suppliers. The capacity of the largest round silo goes up to 4000 tons.

• Square silos Square silos are ideal for the use of inside batching and holding purposes. Square silos can be used in dual row placement, with capacities of 6 - 15 tons. For bulk materials, square is the right shape for maximum capacity. Square silos should be cladded if used outside for the overload bridge out-loading system.

-

Magnet Box

Dalein Agriplan uses magnet boxes, fitted with powerful permanent magnetic plates, to remove metal particles from raw material and animal feed in transport. This decreases the possibility of metal parts ending up in the final product or damaging machinery. These boxes can be used in other food and plastic industries as well. The sizes of the magnet boxes can be custom designed to fit your plant’s needs.

-

Valve Box

A Valve Box, (flap box or diverter valve) is used to divert or direct the material in multiple specific directions for total mobility and plant control. This improves the flow line and direction of product, to suit each plant. It increases productivity due to less man hours used to direct the material. Dalein Agriplan has a variety of valve boxes, custom build to suit every plant.

-

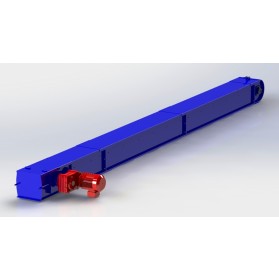

Chain Conveyor

The chain conveyor is a reliable means of transport for the continuous transfer, horizontal or inclined, of granulated and powdered products. Chain conveyors are suitable for the transport of high capacities over long distances. It can be designed with intermediate outlets and slides. They are usually electro pneumatic driven, but manually controlled designs can be done.

Dalein Agriplan's chain conveyers are designed for dust proof transport of raw materials and finished products. Our chain conveyors are manufactured in a modular system and can be supplied in the exact required length. We systematically strive for simplicity and so Dalein has designed 3 types of chain conveyors that can provide various capacities of feed to suit the client’s needs:

• No waste: A design unique to Dalein Agriplan. The product is pulled from the intake to the outlet along the bottom of the chain as a gliding mass. If not discharged properly, products get rotated back to the beginning of the cycle so it can be discarded through the sluice at the position required. This cycle is continuous, which ensures zero product wastage.

• Transfer: A chain transports the product horizontally in one direction from the inlet to the outlet.

• Incline: The angle chain conveyor is suitable for work at different angles not exceeding 52° and often takes a product from one machine to the next at different levels.

-

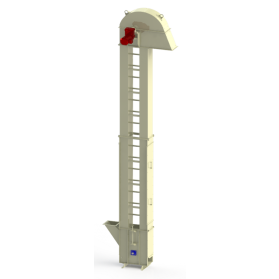

Bucket Elevator

Bucket elevators are very efficient equipment for the continuous, vertical, dust-free transport of granulated and powdered bulk materials. Dalein Agriplan's bucket elevators are designed to stand on its own with or without support or in a structure. Material is fed into the boot of the elevator via an integrated inlet chute. The elevator belt runs over a pulley both at the top and at the bottom of the elevator. Buckets are attached and fitted at equal spaces to the belt by specialised elevator bolts which have a flat head, thereby minimizing interference with the head and tail end pulleys.

The goal is always to minimise spillage and thereby increase efficiency, while avoiding and designing around potential high-wear areas.

The top pulley is driven while the bottom pulley is fitted with a tensioning device. The base can be fitted with one or two intake chutes.

When an elevator is discharging, both gravity and centrifugal forces play an important role. The design of the inlet and discharge connections has a major effect on the capacity of the elevator. The content and shape of the elevator buckets, the bucket spacing, the belt speed and the pulley diameters also play an important role.

Some of the key design objectives are:

• Optimal performance

• Life span

• Maintainability