Products

-

Conveyor Belt

The Sewing Conveyor belt is usually used beneath the Nett Weigher. The feed is dispatched into a bag which is then released onto the conveyor belt. The conveyer belt transports the open bag of feed at the correct speed through the sewing machine. The sewing machine stitches the bag of feed shut, which is now ready to be transported. Dalein Agriplan provides 2 types of conveyors - horizontal or inclined - to suit the client’s needs.

-

Conditioner

The stainless-steel conditioner mixer has large paddles whose height and angle can be

adjusted to provide homogenous mixing and a hygienic process.The robust, low-maintenance machine can be combined with a feeder screw and steam set

and contributes to an optimum absorption of steam and liquids.There is a choice of two options: a standard conditioner mixer and an insulated, electrically

heated version which minimises the formation of condensation and premature cooling.

Development and engineering details make the difference in this stainless-steel conditioner.

Large-scale paddles whose height and angle can be adjusted generate homogenous mixing

and a hygienic process.The conditioner is often supplied in combination with a feeder screw and steam set.

Homogenous mixing and hygienic process. The benefits are:

- Optimum absorption of steam and liquids.

- Robust housing construction.

- Easy to clean.

- Longer maintenance intervals.

- Simple design.

-

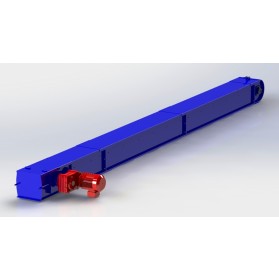

Chain Conveyor

The chain conveyor is a reliable means of transport for the continuous transfer, horizontal or inclined, of granulated and powdered products. Chain conveyors are suitable for the transport of high capacities over long distances. It can be designed with intermediate outlets and slides. They are usually electro pneumatic driven, but manually controlled designs can be done.

Dalein Agriplan's chain conveyers are designed for dust proof transport of raw materials and finished products. Our chain conveyors are manufactured in a modular system and can be supplied in the exact required length. We systematically strive for simplicity and so Dalein has designed 3 types of chain conveyors that can provide various capacities of feed to suit the client’s needs:

• No waste: A design unique to Dalein Agriplan. The product is pulled from the intake to the outlet along the bottom of the chain as a gliding mass. If not discharged properly, products get rotated back to the beginning of the cycle so it can be discarded through the sluice at the position required. This cycle is continuous, which ensures zero product wastage.

• Transfer: A chain transports the product horizontally in one direction from the inlet to the outlet.

• Incline: The angle chain conveyor is suitable for work at different angles not exceeding 52° and often takes a product from one machine to the next at different levels.

-

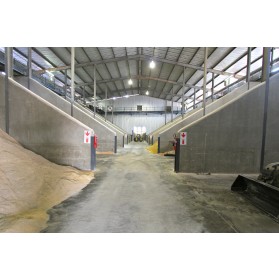

Bunkers

Storage of raw materials requires the utmost care and control at the same time. Many of the world's crops are lost during storage due to the lack of heat and moisture control. No bunker project is too complicated or too simple for Dalein Agriplan – whether the solution applies to large or small bunkers. Open bunkers are ideal for the use of inside batching and holding purposes. For bulk materials, square is the right shape for maximum capacity.

-

Bulk Intake System

Bulk intakes can revcieve raw materials in large amounts. Dalein Agriplan provides highly efficeint raw material intake systems for storage of raw material for futher processing. It consist of a concrete pit or live bottoms along with transport elements to the storage destination.

-

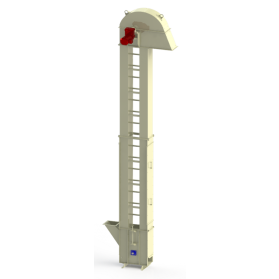

Bucket Elevator

Bucket elevators are very efficient equipment for the continuous, vertical, dust-free transport of granulated and powdered bulk materials. Dalein Agriplan's bucket elevators are designed to stand on its own with or without support or in a structure. Material is fed into the boot of the elevator via an integrated inlet chute. The elevator belt runs over a pulley both at the top and at the bottom of the elevator. Buckets are attached and fitted at equal spaces to the belt by specialised elevator bolts which have a flat head, thereby minimizing interference with the head and tail end pulleys.

The goal is always to minimise spillage and thereby increase efficiency, while avoiding and designing around potential high-wear areas.

The top pulley is driven while the bottom pulley is fitted with a tensioning device. The base can be fitted with one or two intake chutes.

When an elevator is discharging, both gravity and centrifugal forces play an important role. The design of the inlet and discharge connections has a major effect on the capacity of the elevator. The content and shape of the elevator buckets, the bucket spacing, the belt speed and the pulley diameters also play an important role.

Some of the key design objectives are:

• Optimal performance

• Life span

• Maintainability

-

BOA - Compactor

A double-walled mixing chamber in which steam and liquids are added and the mixture is compacted using a hydraulically operated compacting chamber. Generously sized paddles, adjustable in both height and pitch, guarantee a homogenous mixture and a hygienic process. The mixture is introduced into the compacting chamber where a rotating three-roller head, presses it through two conical friction rings.

-

Belt Conveyor

Dalein Agriplan designed a belt conveyor with a wide variety that can meet the client’s feed milling specifications. Belt conveyors can be at an incline of up to a max of 40° and can move up to a speed of ±1.2m/sec. Lengths can be custom designed to suit each feed plant needs with widths varying between 0.9m – 1.5m. Belt conveyors are manufactured with a safety feature to ensure all personal safety as well with an automatic tracking for accurate belt movement and can be used indoors or outdoors.

-

Batching Scale

Our batching scale provides a wide variety of scales batching between 500kg – 2tons. Our unique designed allows for free flowing of difficult products like Lucerne, citrus pulp, silage etc.

-

Batching Bins

We provide batching bins that are designed to hold a valve of between 7-23m³. Dalein Agriplan has a batching block that can hold multiple bins. If more bins are desired, bins can be split or another batching block can be added to the plant.