Products

-

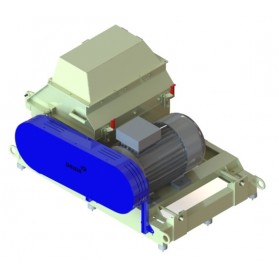

Crumbler

We provide 2 types of crumblers&rsquo

• The local Dalein Agriplan crumblers&rsquo

• PTN crumblers&rsquo

The crumbles’ are specifically designed for crumb production of various feeds. Two spring bolted rollers are specially spaced to gently crumble the pellets into specified smaller pieces. For reliability during use, all the crumbles’ are fitted with specific fluted and machined rollers.

-

Hammer Mills

Various Dalein Agriplan Hammer Mills are available. Capacities range from 3 to 20 tons per hour. Our unique asymmetrical design allows for optimum power-to-capacity ratios without aspiration. Aspiration remains available to enhance the capacity per kilowatt and ensure more homogeneous particle sizes.

-

Intake Grid

Dalein Agriplan has various standard sizes of intake grids to suit the client’s building and requirements. The grids are designed so that a truck, filled with feed, can drive over it. The grids are level with the floor and are usually on top of a concrete pit or a live bottom.

-

Bulk Intake System

Bulk intakes can revcieve raw materials in large amounts. Dalein Agriplan provides highly efficeint raw material intake systems for storage of raw material for futher processing. It consist of a concrete pit or live bottoms along with transport elements to the storage destination.

-

BOA - Compactor

A double-walled mixing chamber in which steam and liquids are added and the mixture is compacted using a hydraulically operated compacting chamber. Generously sized paddles, adjustable in both height and pitch, guarantee a homogenous mixture and a hygienic process. The mixture is introduced into the compacting chamber where a rotating three-roller head, presses it through two conical friction rings.

-

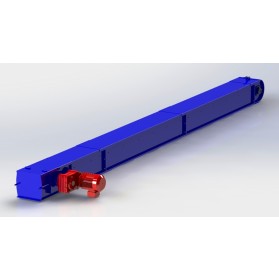

Chain Conveyor

The chain conveyor is a reliable means of transport for the continuous transfer, horizontal or inclined, of granulated and powdered products. Chain conveyors are suitable for the transport of high capacities over long distances. It can be designed with intermediate outlets and slides. They are usually electro pneumatic driven, but manually controlled designs can be done.

Dalein Agriplan's chain conveyers are designed for dust proof transport of raw materials and finished products. Our chain conveyors are manufactured in a modular system and can be supplied in the exact required length. We systematically strive for simplicity and so Dalein has designed 3 types of chain conveyors that can provide various capacities of feed to suit the client’s needs:

• No waste: A design unique to Dalein Agriplan. The product is pulled from the intake to the outlet along the bottom of the chain as a gliding mass. If not discharged properly, products get rotated back to the beginning of the cycle so it can be discarded through the sluice at the position required. This cycle is continuous, which ensures zero product wastage.

• Transfer: A chain transports the product horizontally in one direction from the inlet to the outlet.

• Incline: The angle chain conveyor is suitable for work at different angles not exceeding 52° and often takes a product from one machine to the next at different levels.

-

Valve Box

A Valve Box, (flap box or diverter valve) is used to divert or direct the material in multiple specific directions for total mobility and plant control. This improves the flow line and direction of product, to suit each plant. It increases productivity due to less man hours used to direct the material. Dalein Agriplan has a variety of valve boxes, custom build to suit every plant.

-

Batching Bins

We provide batching bins that are designed to hold a valve of between 7-23m³. Dalein Agriplan has a batching block that can hold multiple bins. If more bins are desired, bins can be split or another batching block can be added to the plant.

-

Twin Shaft Paddle Mixers

Various Dalein Agriplan Hammer Mills are available. Capacities range from 3 to 20 tons per hour. Our unique asymmetrical design allows for optimum power-to-capacity ratios without aspiration. Aspiration remains available to enhance the capacity per kilowatt and ensure more homogeneous particle sizes.

-

Conveyor Belt

The Sewing Conveyor belt is usually used beneath the Nett Weigher. The feed is dispatched into a bag which is then released onto the conveyor belt. The conveyer belt transports the open bag of feed at the correct speed through the sewing machine. The sewing machine stitches the bag of feed shut, which is now ready to be transported. Dalein Agriplan provides 2 types of conveyors - horizontal or inclined - to suit the client’s needs.

-

Conditioner

The stainless-steel conditioner mixer has large paddles whose height and angle can be

adjusted to provide homogenous mixing and a hygienic process.The robust, low-maintenance machine can be combined with a feeder screw and steam set

and contributes to an optimum absorption of steam and liquids.There is a choice of two options: a standard conditioner mixer and an insulated, electrically

heated version which minimises the formation of condensation and premature cooling.

Development and engineering details make the difference in this stainless-steel conditioner.

Large-scale paddles whose height and angle can be adjusted generate homogenous mixing

and a hygienic process.The conditioner is often supplied in combination with a feeder screw and steam set.

Homogenous mixing and hygienic process. The benefits are:

- Optimum absorption of steam and liquids.

- Robust housing construction.

- Easy to clean.

- Longer maintenance intervals.

- Simple design.

-

ESW Control System (Locally Develop Control Units)

Electronic System Wrights (Pty) Ltd. By Edwin van de Wiel (Managing Director) Specialising in Industrial Electronic Design and Manufacturing for Automation since 1988. Working with the Dalein Group companies from 1992 for Batch Weighing systems and currently have more than sixty sites running with our systems. The application of Y-Series controllers, our newest control system, are for cost effective Batch Weighing systems including Bulk Materials transport, Pellet Presses, Gross and Net Bagging as used in feed factories. As service to our clients we also design the electrical integration with the industrial plants and help to commission the systems. The Y-Series controller modules are very flexible and are used on standalone systems of between nine and 600 input/output points. These systems become very cost effective as 95% of the software is shared between projects, from the smallest to largest, offering bug free and reliable installation and operation. All the modules run on our real-time communications operating system (RTCOS) with the applications and OS written in "C" for reliability and easy maintenance. Other applications include energy efficient and accurate Industrial Chilling and Freezing, integrated with Energy and Building Management, and SCADA systems. Currently developing a high security Y-Series Gateway that will fully integrate with the internet for IoT and Cloud applications.

-

Weigh Bridge

Dalein Agriplan’s weigh bridge is used to weigh an entire truck or vehicle and their contents. Due to the large scale, it’s usually mounted permanently on a concrete foundation. The load carried is calculated by measuring the weight of the empty vehicle and then with its contents. The weigh bridge is usually located under the overhead bridge to simplify the process.

-

Batching Scale

Our batching scale provides a wide variety of scales batching between 500kg – 2tons. Our unique designed allows for free flowing of difficult products like Lucerne, citrus pulp, silage etc.

-

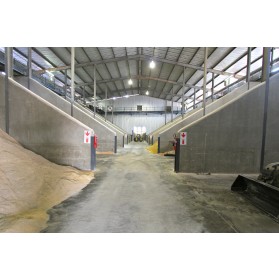

Bunkers

Storage of raw materials requires the utmost care and control at the same time. Many of the world's crops are lost during storage due to the lack of heat and moisture control. No bunker project is too complicated or too simple for Dalein Agriplan – whether the solution applies to large or small bunkers. Open bunkers are ideal for the use of inside batching and holding purposes. For bulk materials, square is the right shape for maximum capacity.

-

Ribbon Mixers

Dalein Agriplan’s Ribbon Mixer has 3 different mixing capacitie:

- 1 ton

- 1.5 ton

- 2 ton

The main benefits of these Ribbon Mixers are that they are cost effective and give a homogeneous mix within 3 to 4 minutes. These mixers are typically used where dry animal feeds are mixed. The Ribbon Mixers have 2 discharging methods:

- Standard double bomb drop doors along the length of the mixer for quick discharging

- A slide gate

-

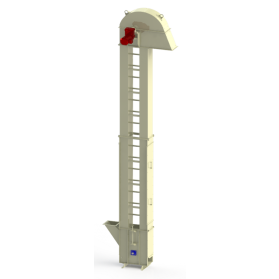

Bucket Elevator

Bucket elevators are very efficient equipment for the continuous, vertical, dust-free transport of granulated and powdered bulk materials. Dalein Agriplan's bucket elevators are designed to stand on its own with or without support or in a structure. Material is fed into the boot of the elevator via an integrated inlet chute. The elevator belt runs over a pulley both at the top and at the bottom of the elevator. Buckets are attached and fitted at equal spaces to the belt by specialised elevator bolts which have a flat head, thereby minimizing interference with the head and tail end pulleys.

The goal is always to minimise spillage and thereby increase efficiency, while avoiding and designing around potential high-wear areas.

The top pulley is driven while the bottom pulley is fitted with a tensioning device. The base can be fitted with one or two intake chutes.

When an elevator is discharging, both gravity and centrifugal forces play an important role. The design of the inlet and discharge connections has a major effect on the capacity of the elevator. The content and shape of the elevator buckets, the bucket spacing, the belt speed and the pulley diameters also play an important role.

Some of the key design objectives are:

• Optimal performance

• Life span

• Maintainability

-

Magnet Box

Dalein Agriplan uses magnet boxes, fitted with powerful permanent magnetic plates, to remove metal particles from raw material and animal feed in transport. This decreases the possibility of metal parts ending up in the final product or damaging machinery. These boxes can be used in other food and plastic industries as well. The sizes of the magnet boxes can be custom designed to fit your plant’s needs.

-

Silo's

Storage of grain and seed products requires the utmost care and control at the same time. Many of the world's crops are lost in storage, due to the uncontrollable development of heat and moisture. Therefore, monitoring and controlling of temperatures are of vital importance in modern grain handling. No silo project is too big or too small for Dalein Agriplan – whether the solution applies to a large or small, square or round silo solution. At Dalein Agriplan we provide 2 types of silos for your convenience:

• Round silos Round silos are suitable for large storage capacities. Dalein Agriplan provides the option of round silos manufactured by our trustworthy suppliers. The capacity of the largest round silo goes up to 4000 tons.

• Square silos Square silos are ideal for the use of inside batching and holding purposes. Square silos can be used in dual row placement, with capacities of 6 - 15 tons. For bulk materials, square is the right shape for maximum capacity. Square silos should be cladded if used outside for the overload bridge out-loading system.

-

Liquid Dosing Unit

Dalein Agriplan provides liquid additions of water, animal oil and molasses that is added by a volume based flow meter into a mixer, fat coater, lick plant or a conditioner.

-

Pellet Press

Dalein Agriplan's expertise in the pelleting process focuses on creating a pellet that is durable and tough enough to resist breakage during handling. Our pelleting press enables companies to pellet a wide variety of different raw materials. Pellet machines can be fitted with a twin or single conditioner with a recursion time barrel.

The pelleting process begins with a conditioning process where steam is homogeneously mixed with the ingredients at a temperature of up to 75°C. A knife system systematically cuts the pelletized product from the die and the still warm pellets proceed onwards for cooling.

Optimum meal preparation is essential for maximum press capacity. Meal, molasses and steam are mixed in the (conditioning) mixer to form a mixture that can easily be pressed. The entire supply of meal, steam and liquids is controlled by a fully automated PLC system.

-

Overhead Bridge

The overhead bridge is usually located across the weigh bridge, to simplify the process of before and after weighing. The overhead bridge conveys the final product that is ready to be transported. Dalein Agriplan has designed the overhead bridge to transport the final product from inside the plant to outside, with a covered gantry for easy maintenance and to protect the equipment from the weather conditions South Africans may encounter. The dispatch is designed to minimise product waste.

The overhead bridge is a set of bins for the final product, located on the outside of the feed mill. It’s designed so that a feed-tanker can drive underneath the bridge, where the feed is released from the bins into the feed-tanker. A large weigh-scale is also fitted on the ground under the bridge, to weigh the feed-truck.

-

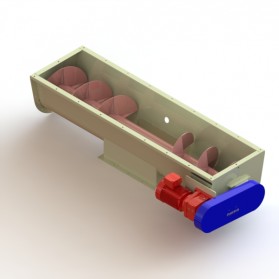

Auger

Each design is unique in its own form to suit varied situations. Dalein provides a variety of specifically designed augers, for horizontal or inclined transport of bulk goods and materials. Augers are constructed from durable materials and provide an efficient, economical and dependable conveying medium, reflecting the benefits of our sound engineering experience.

Advantages of Dalein Agriplan's well-designed flight conveyers are clean, low energy consumption and dust free operation Augers, with favourable dimensions and a great degree of maintenance-friendliness as an extra touch.

The transport capacity and the variety of products that can be moved with our augers are exceptionally high. Augers can also be used as discharge and capacity control equipment.

The shaft with the scroll moves the product from the intake trough to the outlet on the drive side. The product does not rotate and just moves forward. The drive group consists of an electrical gearbox motor with optimal frequency controller for full control. Equipment and accessories are manufactured both for straight forward conveyors and for complete systems in large turn-key projects.

-

Steam

Adding steam to the production process for animal feeds improves the compressibility (an increase in the press capacity of 20% is no exception) and the condition of the laying mash, among other things. Steam inactivates micro-organisms while the sensory properties (including aroma, taste and texture) of the product mix are retained.

For the production of high-quality (dry) steam – the quality is determined by pressure and temperature – PTN supplies steam lines and steam injection systems on mixers, presses, expanders and compactors.

Characteristic of the injection systems is the volume-increasing drainage vessel after the reducing unit in which a steam flash, and thus superheated dry steam, is generated.

The compact systems are available with a capacity of 150 - 2.500 kg/hr, are easy to install and use relatively little energy.

-

Belt Conveyor

Dalein Agriplan designed a belt conveyor with a wide variety that can meet the client’s feed milling specifications. Belt conveyors can be at an incline of up to a max of 40° and can move up to a speed of ±1.2m/sec. Lengths can be custom designed to suit each feed plant needs with widths varying between 0.9m – 1.5m. Belt conveyors are manufactured with a safety feature to ensure all personal safety as well with an automatic tracking for accurate belt movement and can be used indoors or outdoors.